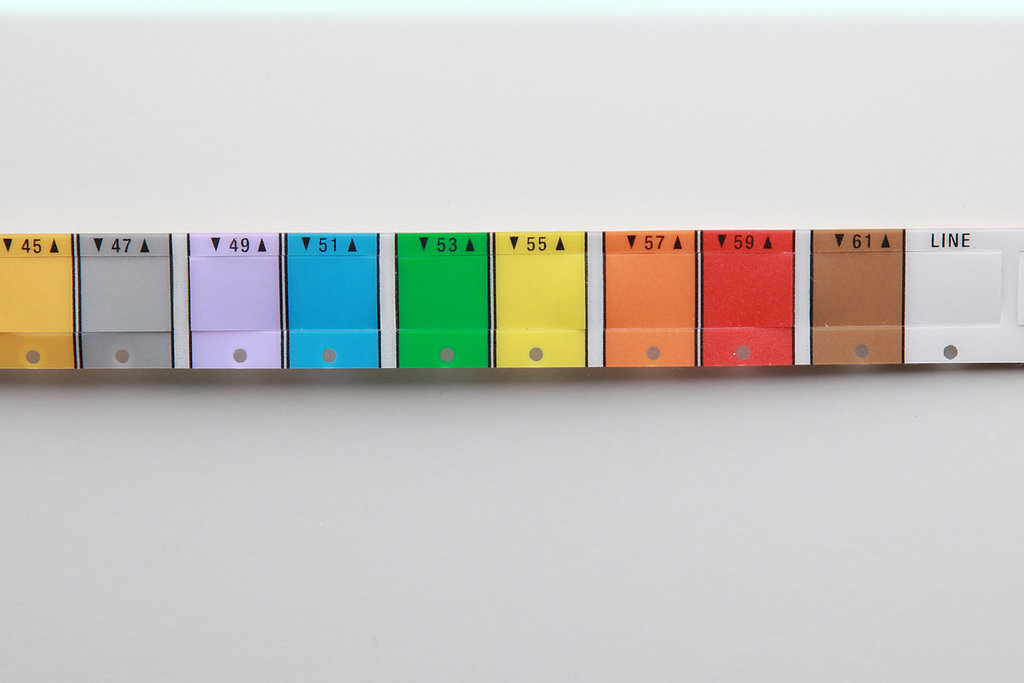

Overlays

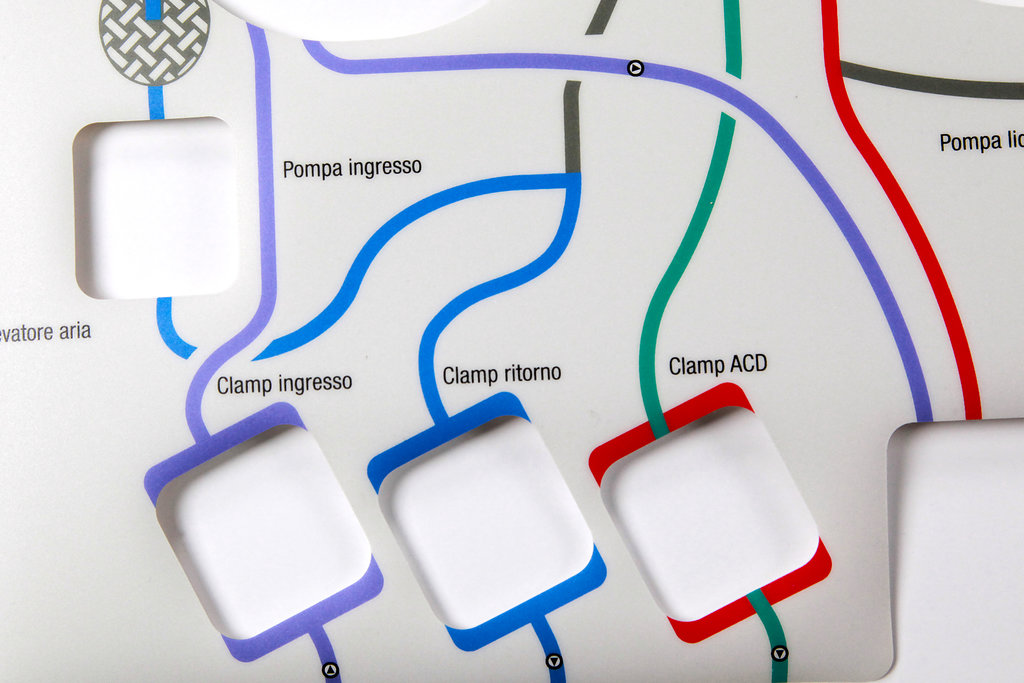

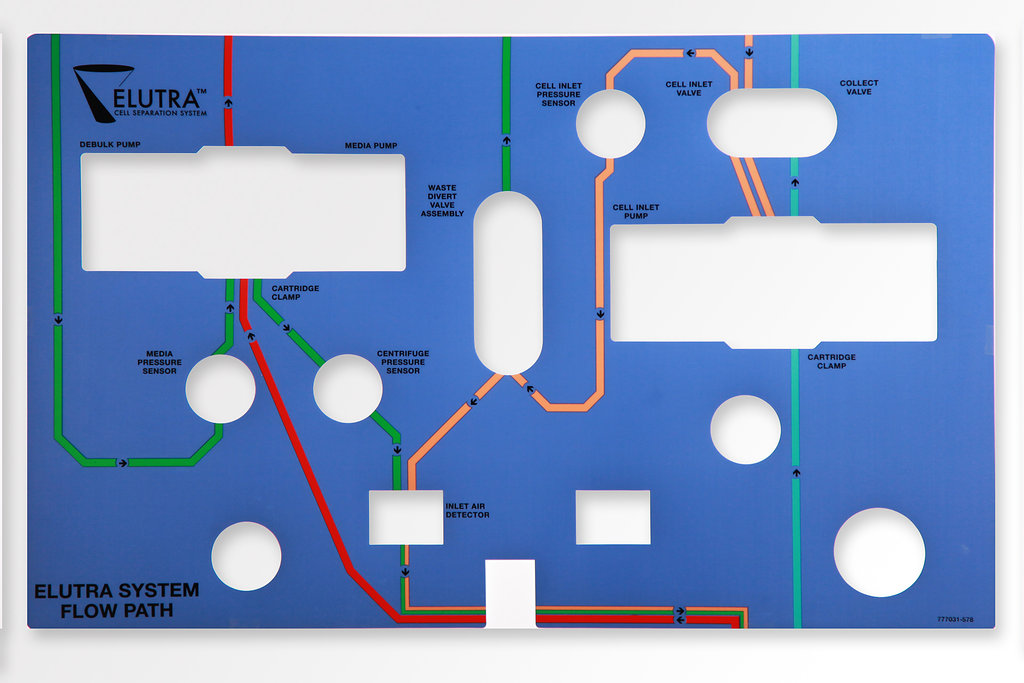

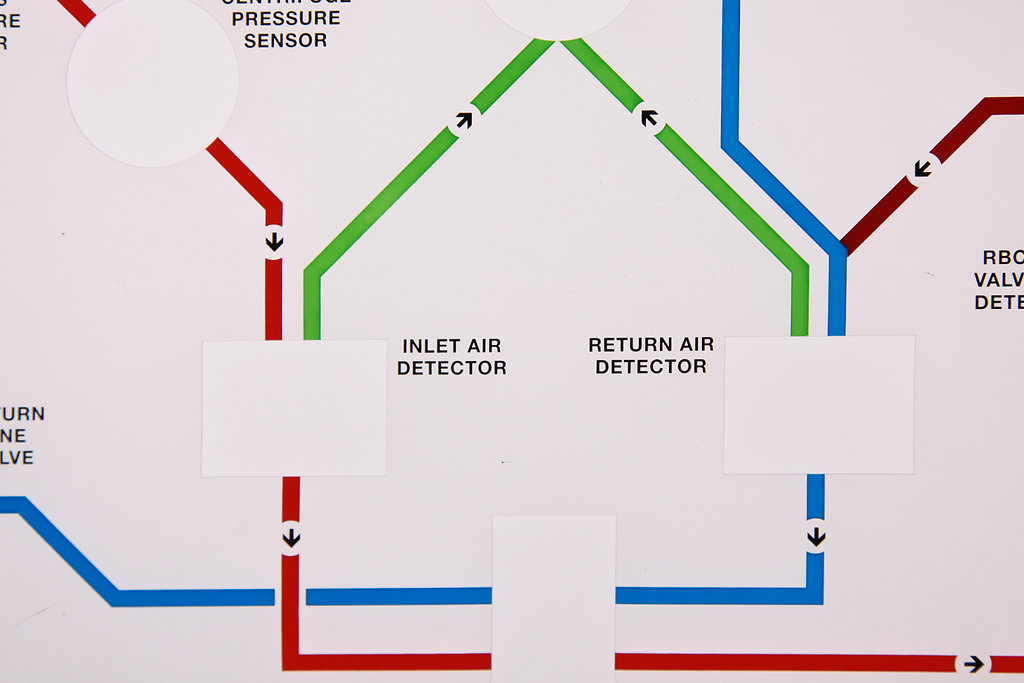

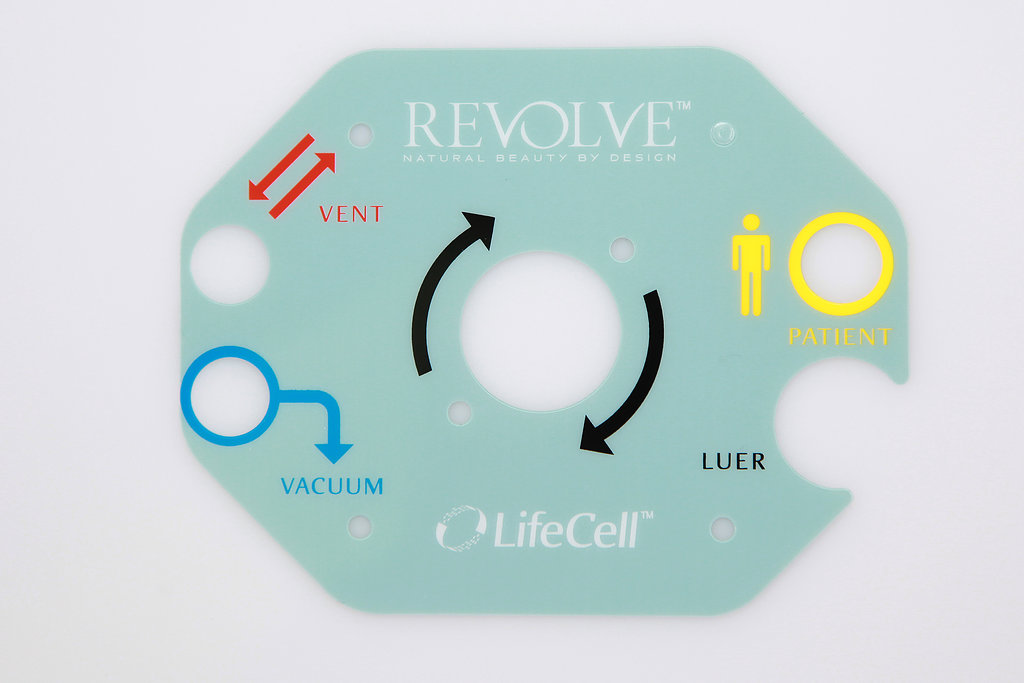

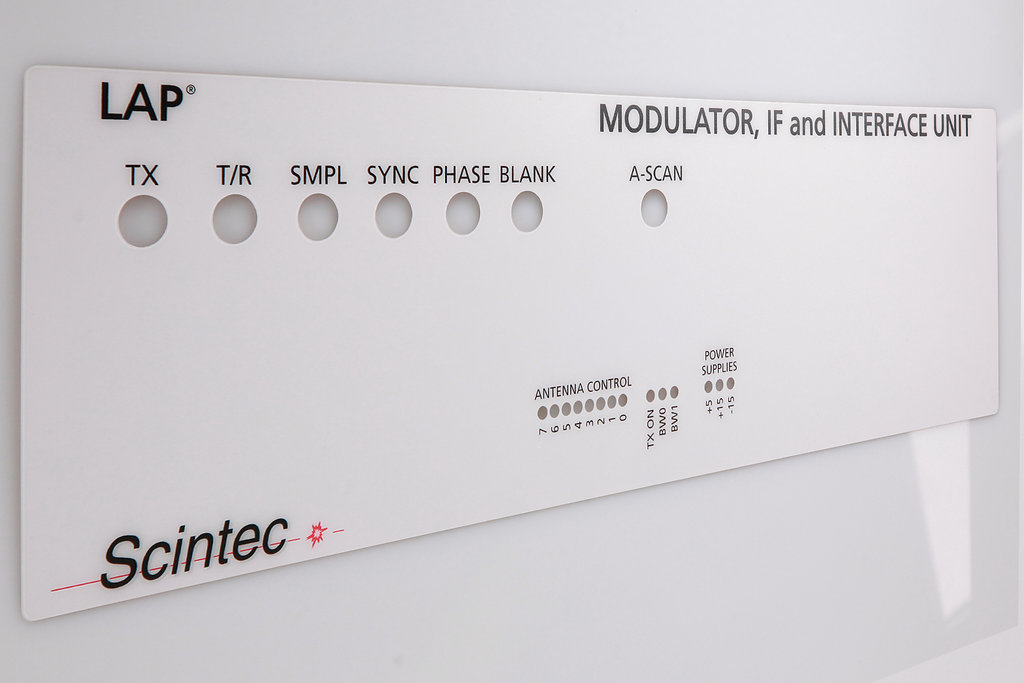

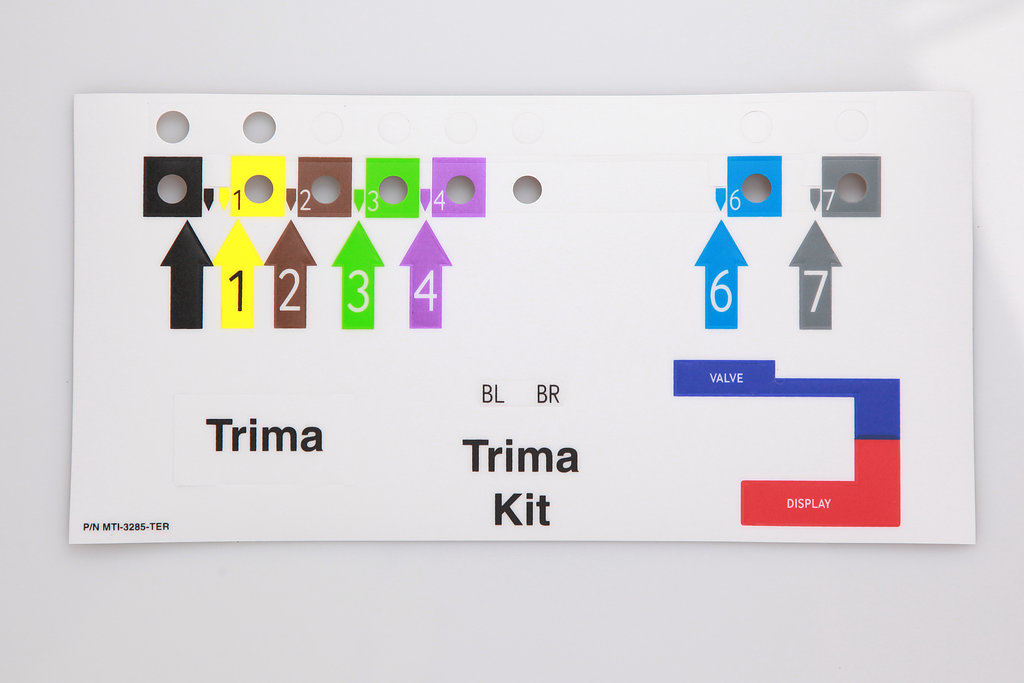

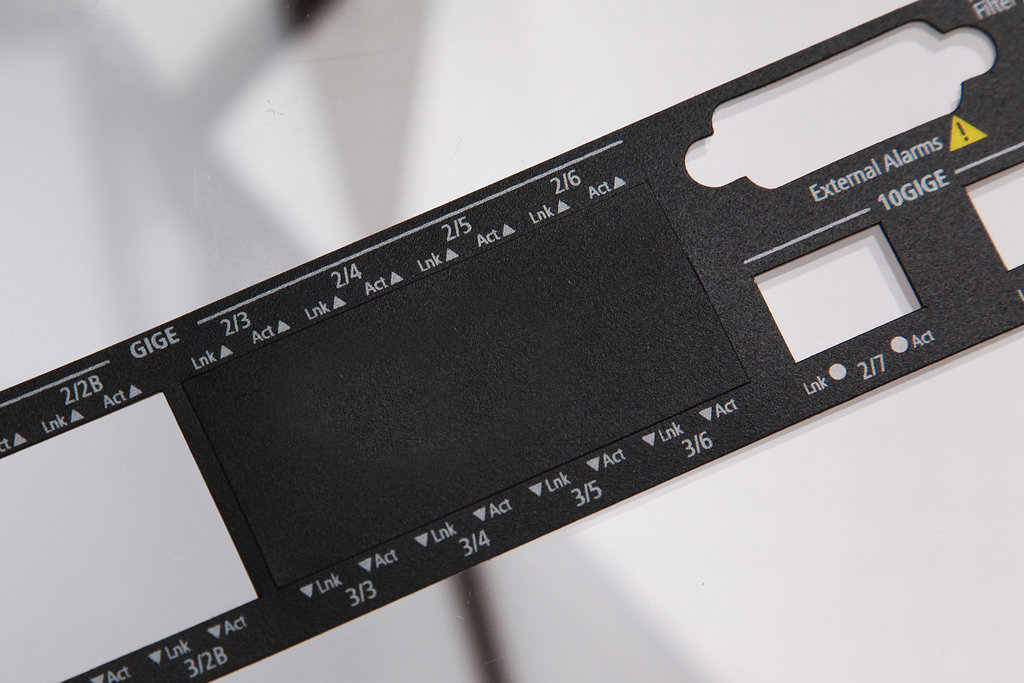

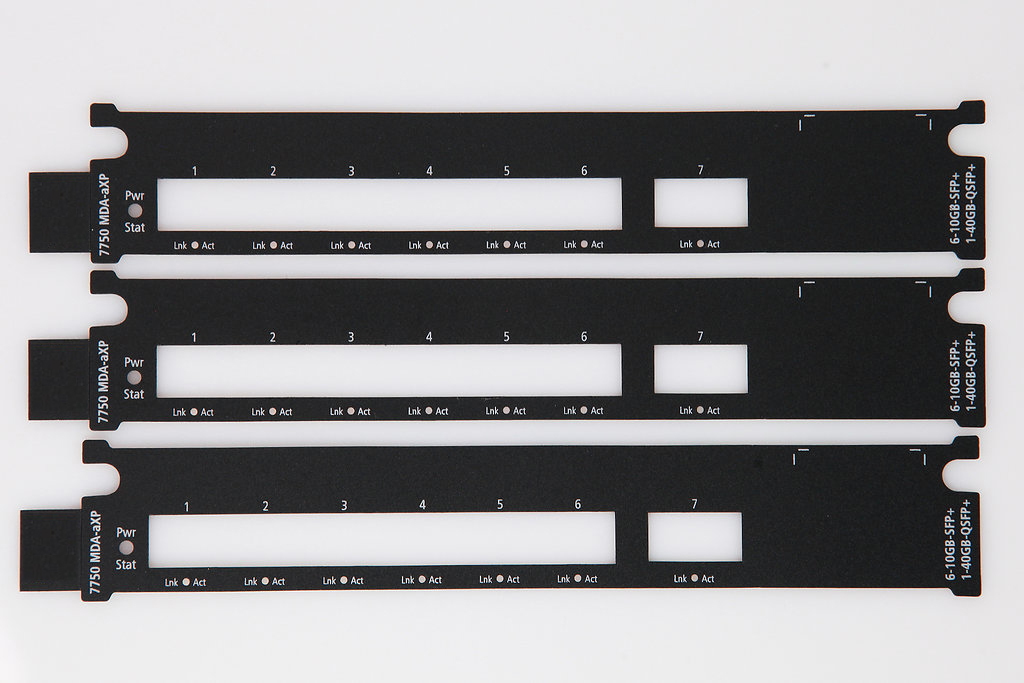

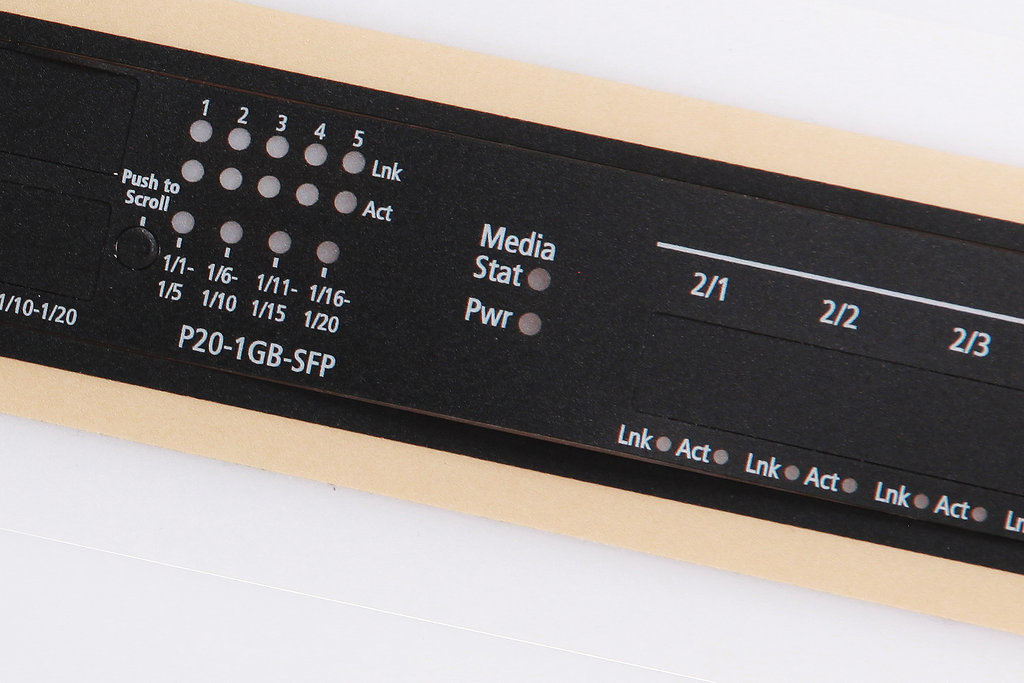

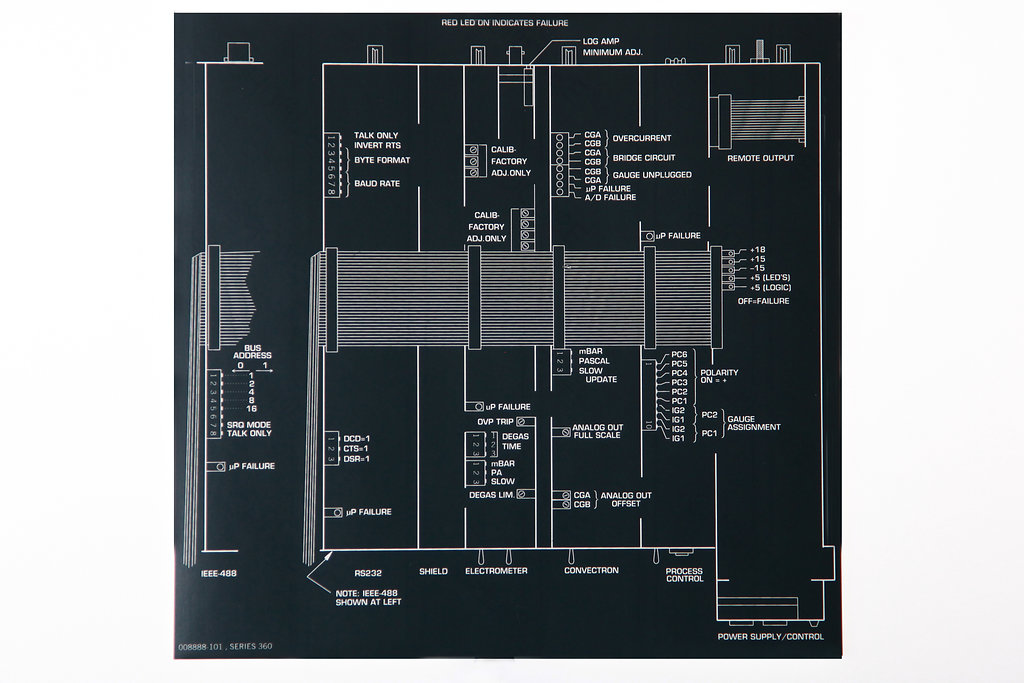

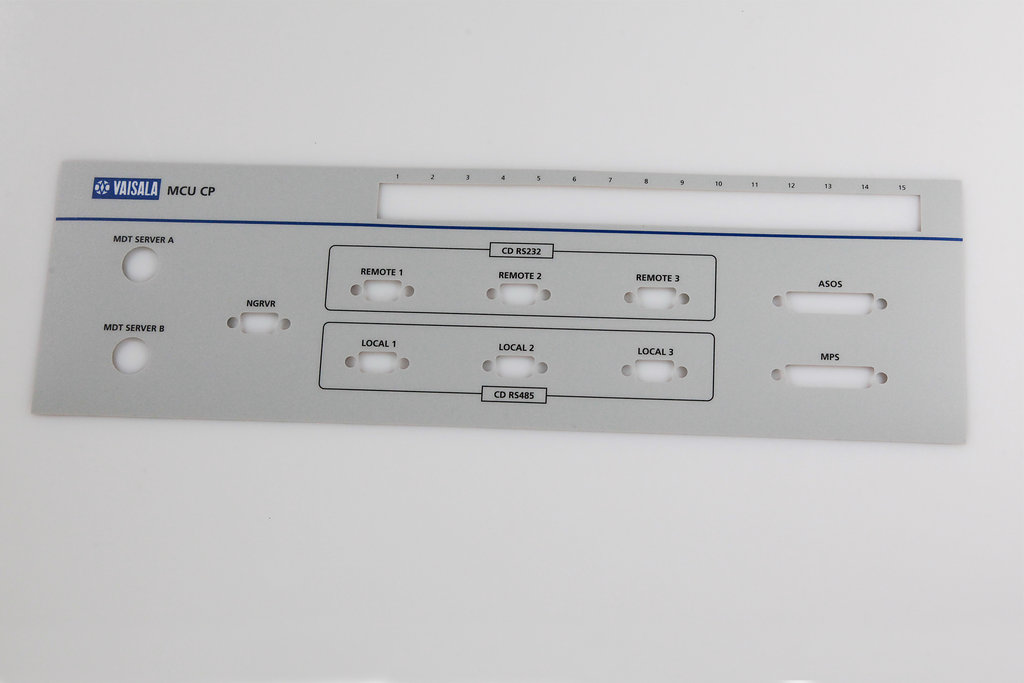

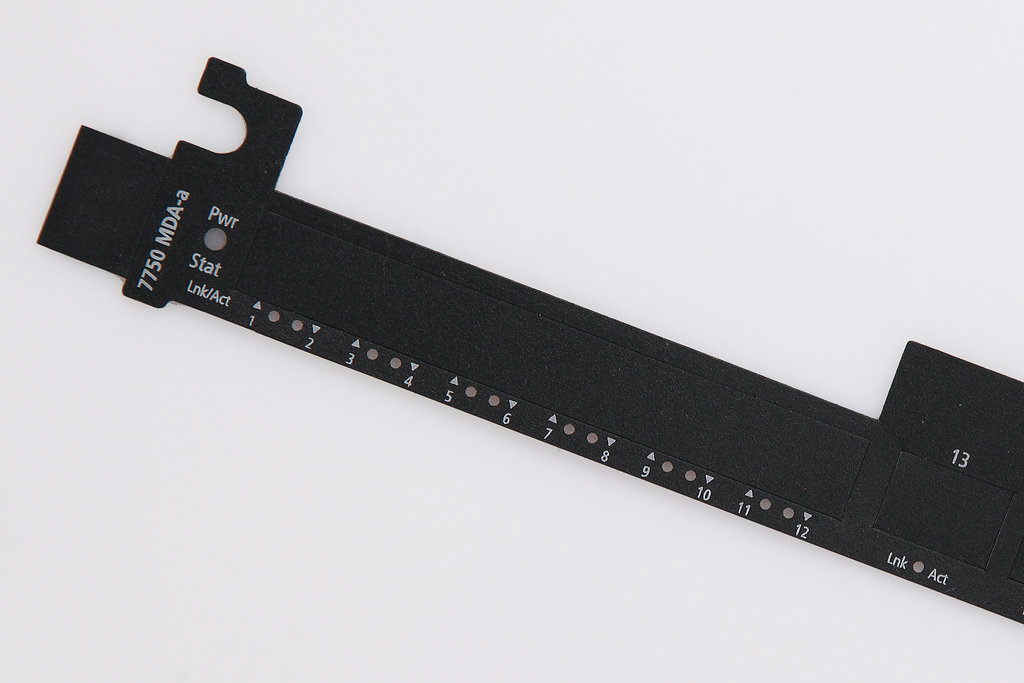

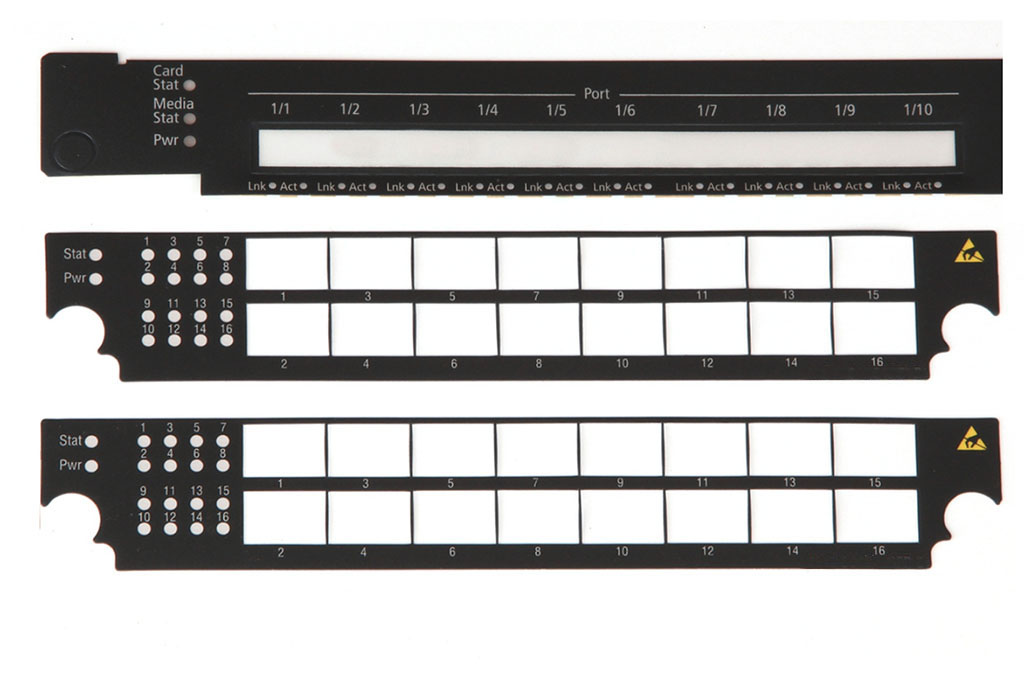

Overlays are a unique and particularly important graphic component of your equipment. Graphic Overlays provide both a protective surface as well as a communication platform to create a user-friendly, purposeful and well-designed customer interface that conveys the exceptional quality and functionality of the equipment it represents.

The Graphic Overlay is often the primary visual aspect of your equipment that your customer will see and feel; a well-designed and constructed overlay will enhance the quality and value of your product. Allow Mar-Tek associates to bring their experience, knowledge and focus on Quality and Value to your project and we’ll work together to make your product the best it can be.

Mar-Tek second-surface screen prints (digital printed overlays are also offered) your graphic content, meaning the overlay material itself protects the printing as well as the equipment beneath it. Using UV (Ultraviolet light cured inks) we can also add smooth windows or selective custom textures to the surface of your overlays to provide a unique look that separates your quality product from your competition.

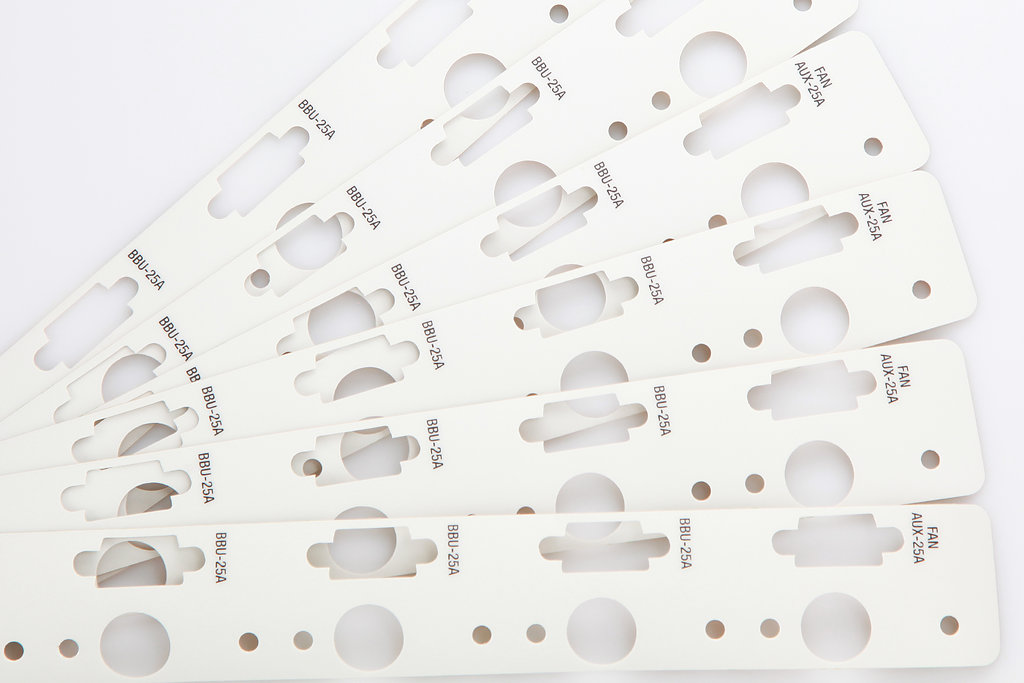

Choosing the correct adhesive for the underlying equipment or part surface is an important step in the graphic overlay design. Mar-Tek utilizes a wide selection of durable 3M Industrial adhesives, which we either roll-laminate to the back of the overlay or selectively apply to allow for adhesive free areas, such as may be required for clear windows, underlying membrane switches or open areas in the product surface. Consideration of factors such as low surface energy (LSE) application surfaces such as powder coated paint surfaces, high temperature operating conditions, extreme outdoor weather conditions and other factors must be considered for best product performance.

After the adhesive is applied to the printed graphic overlay, Mar-Tek typically cuts the overlay to its final shape and cut out features using laser cut Steel Rule Dies, holding tolerances of +-.010” print to cut. Cut tolerances of +-.005” can be held as the finished construction may require and is reviewed by our professionals on a case by case basis. Precision die cut production design includes incorporating through-cutting and kiss-cutting different aspects of the same overlay, allowing select portion of the overlay to be peeled off separately and intact from the adhesive liner paper.

As with all our production, the final product is 100% inspected and checked to make sure it meets all specifications before it is shipped to our customers.